Scalable Innovations based on strong fundamentals “Chemistry and Biology First” with Engineering interventions is an integral part of QPAT’s scale up strategy. The company’s process development and Engineering expertise is enabling us to deliver increasingly superior technologies.

QPAT has pioneered in certain technologies like adsorptive and chromatographic separations, membrane filtration, drying, continuous reactors and extractor etc. for pharma, biotech, food and feed industries.

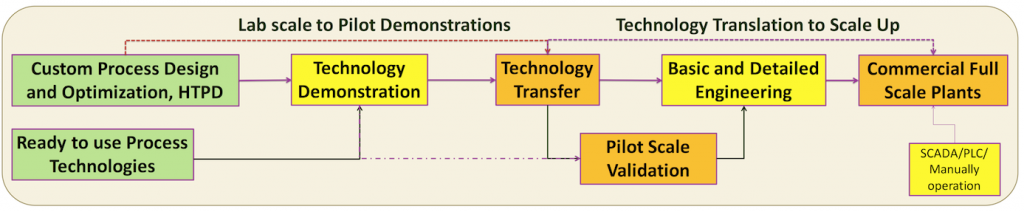

Scale Up activities at QPAT consists of

- Demonstration of process and quality of product at lab scale,

- Translating process from lab scale to pilot scale with fine tuning, followed by

- Commercial scale with commissioning and SOP/BMR documentation

This involves

- Collecting process engineering data

- Generating material and energy balance

- Generating process flow diagrams (main plant, utilities and ETP)

- Equipment list and utility consumption with utility list

- Time scheduling and building contiguous process (if possible)

- Detailed engineering of process with P&ID, process controls, automation etc.

- Cost dynamics (CAPEX and OPEX) with breakeven and ROI calculations

- Vendor identification, equipment specification

- Commissioning and post commissioning services

- Assisting marketing team with technical inputs on product obtained from the process

- Training of manpower at customers site (e.g. column packing and validation)

Equipment supply

- Pilot scale adsorptive and chromatographic systems

- Commercial scale adsorptive and chromatographic systems

- Food and organic solvent dehydration system